We are the

giants of belting

I’m looking for

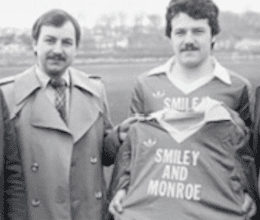

Our story began in 1979 in a small barn in Northern Ireland, where we supplied conveyor belting and services to local quarries. Since then, we've changed a lot, but our purpose remains the same. We're on a mission to revolutionize belt conveying. Why not join us on our journey?

Read our storyOur most popular products

Our story so far

We're on a mission to revolutionize belt conveying

Since we began life as a service company in 1979, we always strived to do things better. Whether it was to strengthen a vulcanised belt joint or improve on-site health and safety – we led the way. Now a global manufacturer, we thrive on a culture of continuous improvement, working closely with our customers and partners to develop product innovations which impact our industry for the better.

Meet the team

It’s our vision to be the number one across our belt conveying world. To us, that means going the extra mile for our customers and striving for excellence throughout our business.

Industries we serve

-

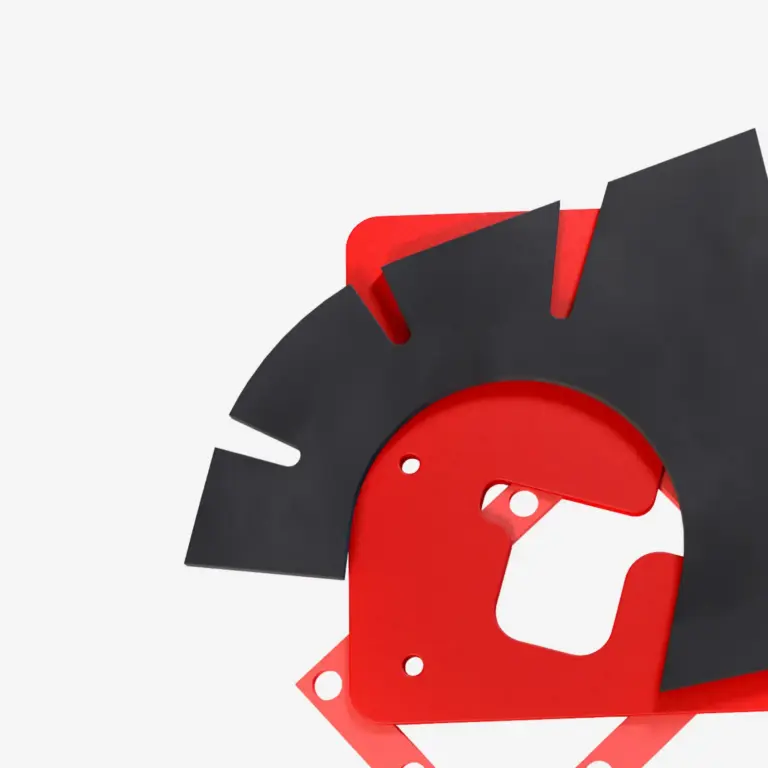

Construction and Aggregates

We're proud to be the number one supplier of endless belts for mobile crushing and screening equipment globally.

-

Recycling and waste management

Problem-solving conveyor belts and components designed for static and mobile recycling and materials recovery plants. Proudly maximising uptime across the world of materials recovery, recycling and waste management.

-

Agricultural

Whether in the field or in the factory we can supply the product you need to keep you moving.

-

Road construction

Our belts are building 'endless' new roads across the world.

-

Environmental

Our belts don’t just carry rocks. The reputations of the world’s biggest manufacturers are on there, too.

Giant Leap

Our “Giant Leap” strategy drives innovation and sustainability, aligning with the UN’s Sustainable Development Goals. We’re reducing our environmental impact, supporting communities, and paving the way toward a better future for our industry.

Learn moreConveyor belt handbook

Created in collaboration with our internal product experts and bringing together 45 years’ experience in the conveyor belting industry, our conveyor belt handbook is an essential resource for best practices, providing detailed guidelines on choosing the right conveyor belt and troubleshooting common conveying problems.

Get your copy