Solutions

Problem-solving products to transform your operations.

We get it

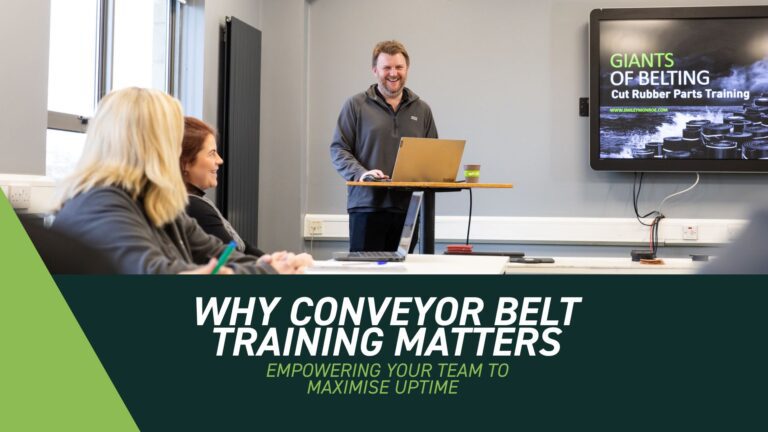

Downtime costs money. Spillage wastes resources. Damaged belts can bring everything to a grinding halt. That’s why we design problem solving products that address common conveyor challenges. Successful conveying might start with the right belt, but when combined with our range of conveyor components, we deliver maximum uptime, process efficiency and belt lifespan.

Reduce downtime

When conveyors stop, everything stops. Smiley Monroe is in the business of keeping you moving—that's why we design and deliver smart, durable solutions for a variety of time-consuming challenges. Save time, money, and stress with our range of products for downtime reduction—from quick-install replacement belts to low-maintenance rollers and wear parts.

Minimise material spillage

Every particle is precious. Loose material doesn't just cost you product—it represents chunks of time, efficiency, and safety falling to the ground. Smiley Monroe offers a range of smart, high-performance solutions to keep your material where it belongs—on the belt. We have products that minimize spillage at every point along your conveyor system—from belt alignment to skirting and stability.

Resolve belt tracking

Poor belt tracking leads to spillage, uneven wear, and costly downtime. Our precision-engineered products are designed to keep your conveyor belt aligned and running true — no matter the load or environment. From advanced rollers to skirting and scrapers, every component plays a part in keeping your material handling smooth, efficient, and trouble-free. Stop belt drift before it stops you.

Improve operational safety

In demanding environments, safety and efficiency go hand-in-hand. Our safety-focused products help you prevent accidents before they happen, from reducing spillage and slippage to protecting your equipment and workforce. We rigorously test every product to deliver peace of mind—so your team can work with assured confidence.

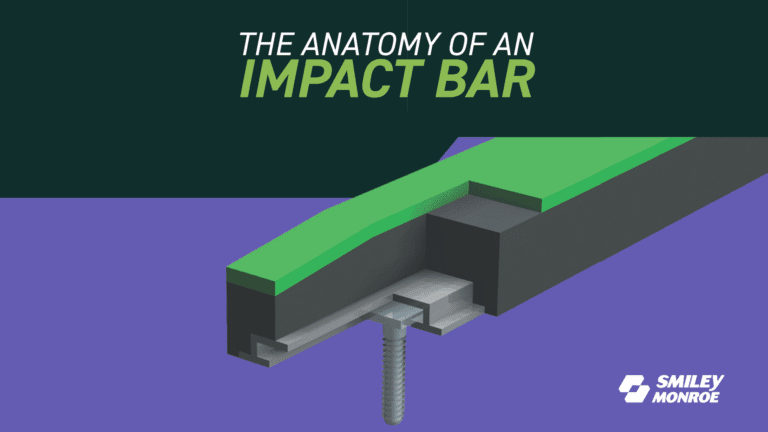

Reduce conveyor maintenance

Every unplanned stop costs you time and money. That's why we design belts and components that stand the test of time—and your materials. Our maintenance-reducing solutions extend belt life, minimize breakdowns, and keep your system running reliably, shift after shift. Explore our reinforced belting, abrasion-resistant skirting, and impact-reducing rollers that are built to work and made to last.