Construction and Aggregates

We're proud to be the number one supplier of endless belts for mobile crushing and screening equipment globally.

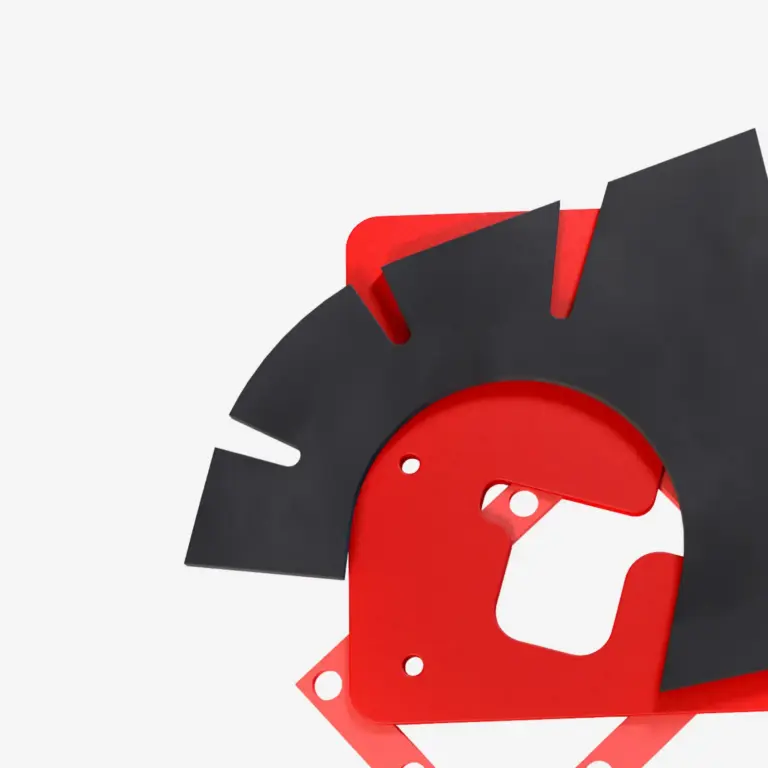

Our belts are built for the hard hits

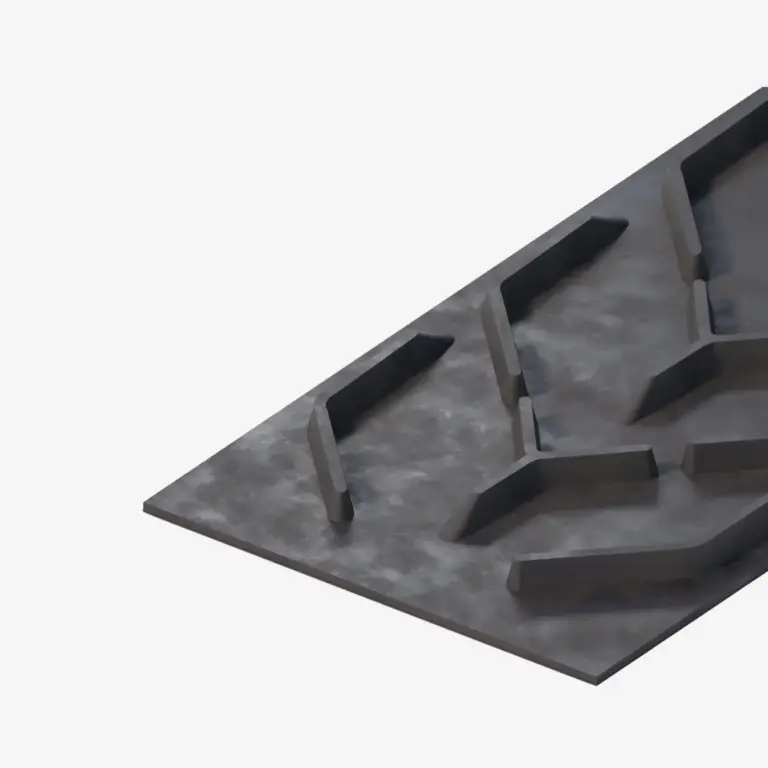

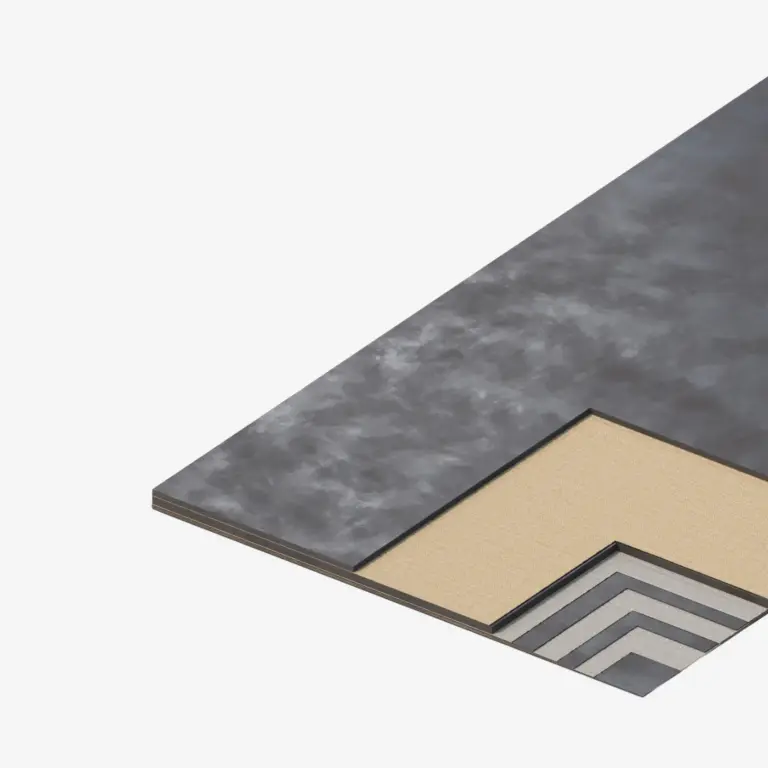

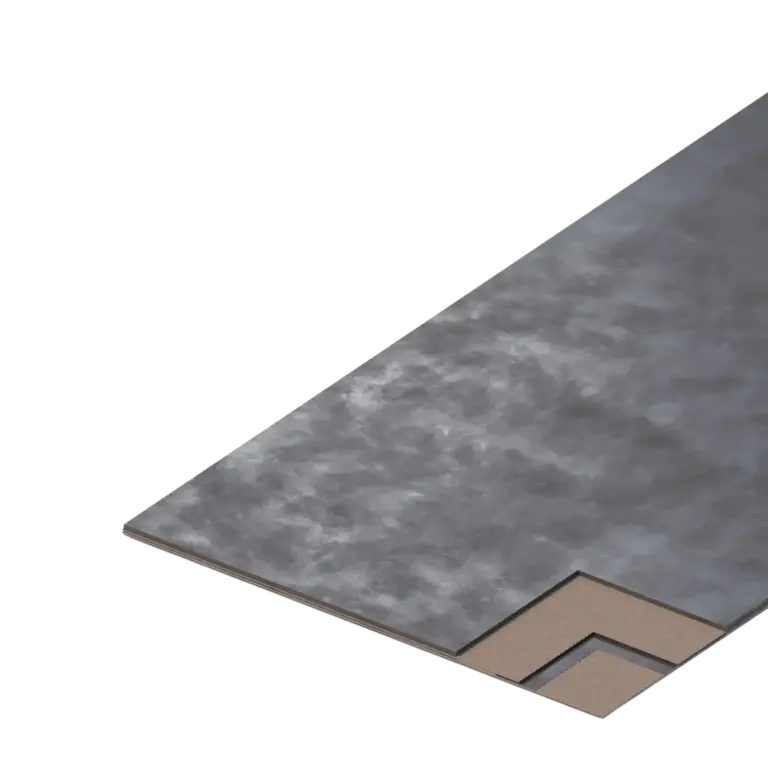

Perfect for handling the hard hits from the harshest materials, such as concrete and steel rebar, we recommend our premium ToughFlex® conveyor belting, featuring high-impact, puncture- and tear-resistant heavy-duty covers and a reinforced (straight warp) carcass.

View our products

45 years of technical know-how

We work with all of the top 15 mobile materials processing OEMs globally (and many more amazing brands)

Our warranty has been less than 0.1% for the last 5 years

We produce over 600km of our Endless Conveyor Belt annually

With bases worldwide, we’re proud to stay close to our customers

100% of our customers would recommend us

Our products

We have over 45 years' experience. Let us help you maximize your uptime.

From a small barn to global operations—our cutting-edge conveyor belt solutions for heavy industries have driven us to be the number one partner in the material handling world. Discover why we are the giants of belting.

Discover Smiley MonroeOur clients

“We've been working with Smiley Monroe for over three decades. They provide a great product and speedy service. We've grown as a business because our customers trust the quality of products on our machines and the suppliers we use – that's what makes Smiley Monroe such a valued partner.”

John Pickering

Rapid International, Business Development Manager

“The quality of products we receive from Smiley Monroe is excellent. The opportunity to have after-sales and spare parts like ZIP CLIP© readily available has helped us support our customers and go from strength to strength.”

Stephen Conway

Edge Innovate, Territory Sales Manager

“We keep ZIP CLIP belts in stock because it minimizes our downtime. Smiley Monroe came out and did a survey of our plant and measured all the belts. All our conveyors have belt numbers on them, so if we have a belt that breaks, we take one out of our own stock, we fit it, we ring Smiley Monroe, give them the belt number, and they make us a new one.”

Mark McIvor

RiverRidge, Operations Manager

“With ZIP CLIP®, the clips are already fitted to the joint, so it's ready to go; we just pull the old belt off and fit the ZIP CLIP®. It's much safer, too, as we don't need to take the conveyor out of the machine, so it eliminates a lot of the safety concerns we had with other methods. We like to keep a ZIP CLIP® belt in stock for our most critical conveyors, giving us peace of mind that should anything happen, we can act quickly.”

Kenny Harris

Gaddie Shamrock, Superintendent

Related Case Studies

Switching to ZIP CLIP® as a permanent conveyor belt solution

Smiley Monroe’s Polymer Rollers Reduce Workplace Noise at USA owned Irish Salt Mines

Do you want to reduce Carryback Material?