Article

: News

Not All Conveyor Belts are Created Equal – Benefits of EP Multiply Belts

Updated on: 17 December 2025

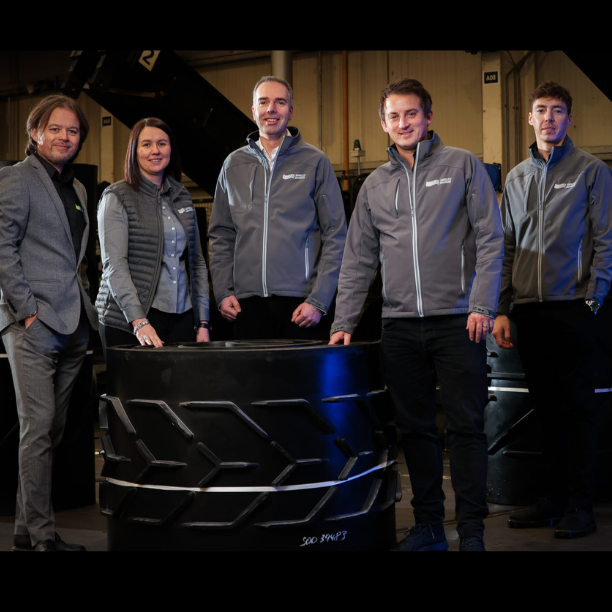

We spend a lot of time on-site with new and potential customers, understanding their operations and solving their problems. Recently our product support team visited a glass recycling plant and surveyed issues they were experiencing with conveyor belts stretching over a relatively short period of time. A stretched conveyor belt results in a lack of proper tension and this in turn causes material spillage at the head drum, the hopper becoming filled up and the material not being conveyed.

The result is a safety hazard in the workplace with material spillage on the floor and inefficient operation with lots of downtimes to unclog the hopper. The customer was also incurring additional costs due to a shortened belt lifespan and needing to purchase a replacement conveyor belt more frequently.

On inspection, our Product Support team quickly identified the problem and was able to specify a Smiley Monroe EP Multi-ply belt for the recycling plant. Smiley Monroe EP Multi-ply belts have a fabric carcass in the conveyor belt (Polyester as the warp and Polyamide as the weft). From years of experience, Smiley Monroe believes that EP is the superior carcass material and delivers the best possible characteristics for belt conveying in several bulk material handling industries including recycling. EP multi-ply belts suffer negligible elongation compared to other carcass materials on the market as well as delivering the following advantages:

· High strength in proportion to weight

· High resistance to impact

· Great flexibility

· Excellent troughability

· Not susceptible to humidity and micro-organisms

The EP Fabric carcass is combined with a wide range of top and bottom cover thicknesses and specifications – all designed for maximum belt wear life and conveying efficiency.

By switching to Smiley Monroe EP Multi-ply belts the customer is reassured that they are purchasing a product which is routinely quality tested in our in-house belt testing lab and manufactured to DIN 22102 standards. By working with our Product Support team, they have the peace of mind that the conveyor belt they have been specified will deliver maximum uptime, maximum process efficiency and maximum wear life.