Article

: News

Anatomy of an Impact Bar: Breaking down the Engineering Behind the Protection

Updated on: 17 December 2025

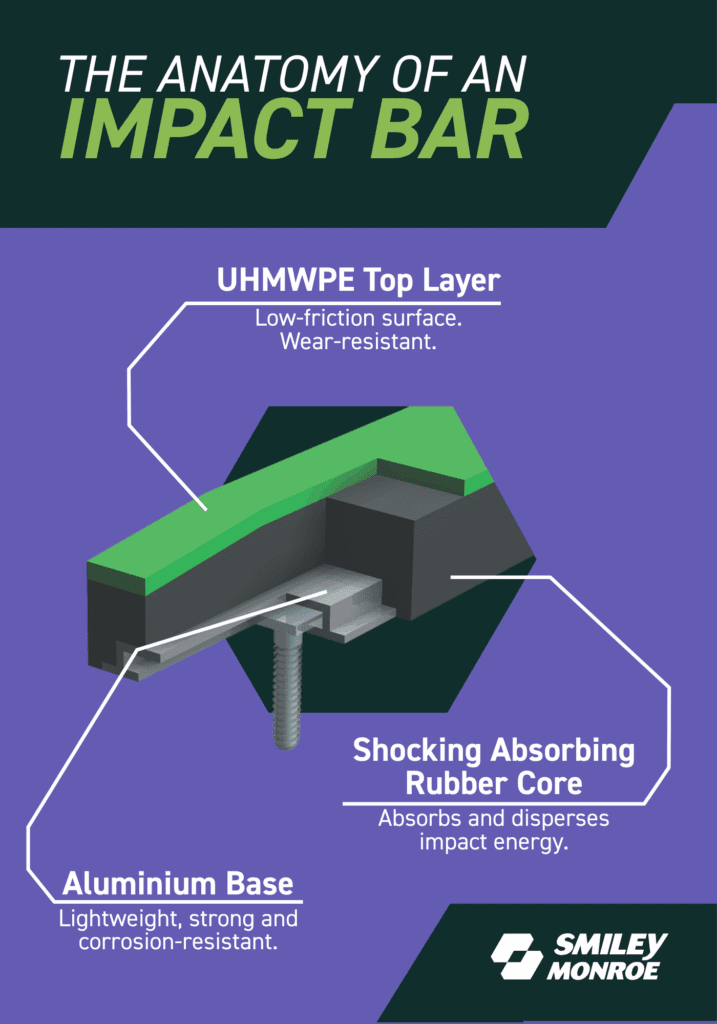

When it comes to conveyor belt protection, the unsung hero at transfer points is the Impact Bar. But what exactly makes it such an effective conveyor component? At Smiley Monroe, we design our Impact Bars with purpose-built materials that work together to absorb shock, reduce belt damage, and extend the life of your equipment. Let’s break down the engineering behind the protection, layer by layer.

1. Ultra-High Molecular Weight Polyethylene (UHMWPE) Top Layer

What It Does:

- Provides a low-friction surface

- Allows smooth belt operation

- Resists wear, abrasion, and heat buildup

Why It Matters:

A smooth top surface means less friction on the belt. That means reduced energy consumption and lower chances of surface wear to the belt and impact bar, especially in high-speed applications.

2. Shock-Absorbing Rubber Core

What It Does:

- Absorbs energy from falling material

- Disperses the impact force evenly across the bar

- Prevents punctures and belt stress fractures

Why It Matters:

This is the heart of the Impact Bar. Without this core, your belt takes the full brunt of heavy or sharp materials, leading to costly repairs or total belt failure.

3. Aluminium Base

What It Does:

- Provides a rigid mounting base

- Ensures easy, secure installation to conveyor frames

- Resists corrosion and maintains bar alignment

Why It Matters:

Your bar is only as good as its foundation. Our lightweight yet strong aluminium base keeps everything in place and simplifies maintenance or replacement.

On Smiley Monroe’s Impact Bars, every layer is there for a reason. Each one plays a critical role in protecting your belt systems, guaranteeing less downtime and lower maintenance costs.

To keep your systems moving smoothly, contact our team of specialists today to discuss the best Impact Bar solutions for your application.