PU Conveyor Belt Cleaners & Scrapers

Reduce downtime, maximise your uptime.

Heavy duty blade designed to keep a cleaning edge as it wears.

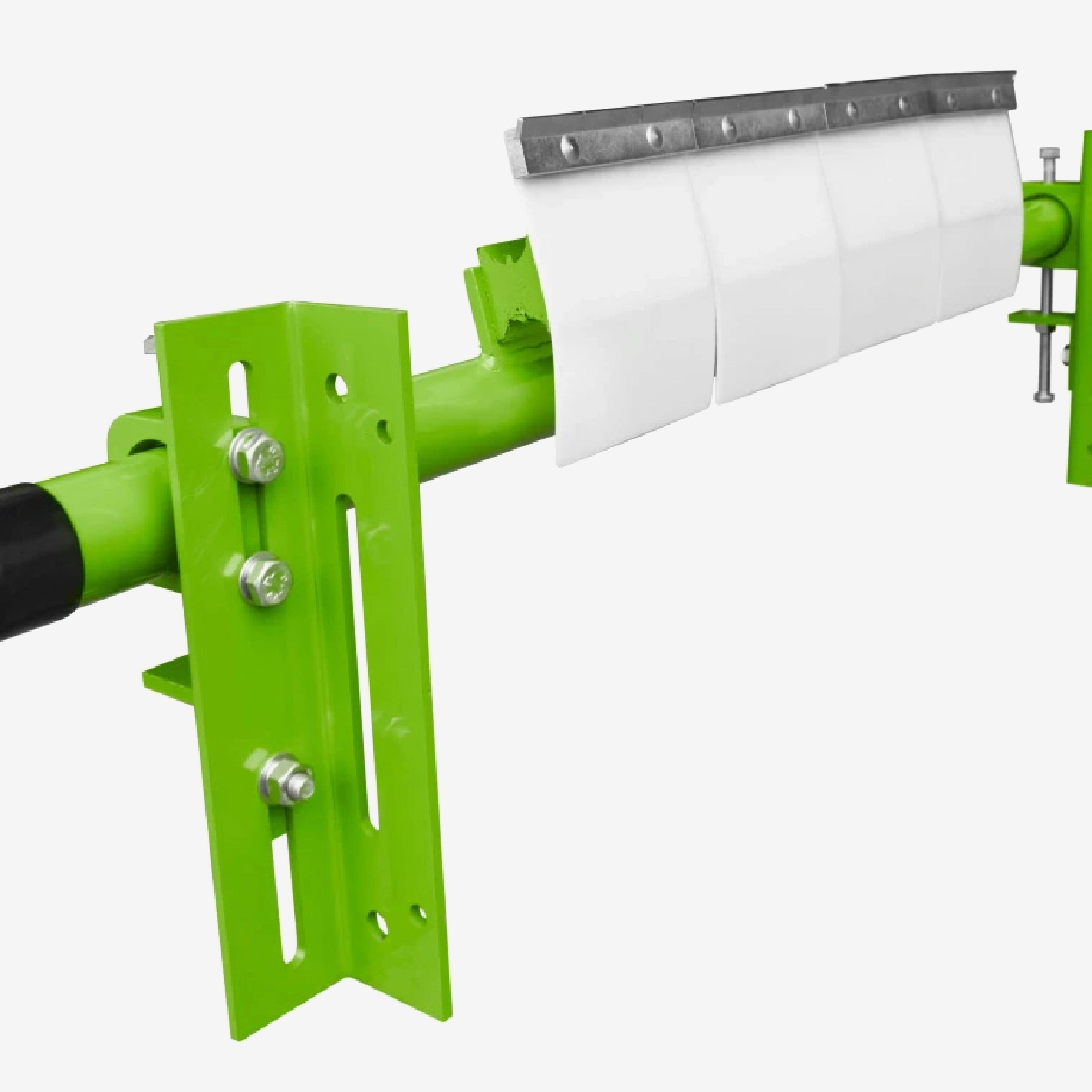

Smiley Monroe Cover Clean conveyor belt cleaning system is specially designed to minimize conveyor downtime associated with a build up of carryback material.

Our range is designed with your industry in mind and features primary and secondary cleaners with either polyurethane (PU) or tungsten carbide blades to ensure consistent cleaning efficiency. All our belt cleaners can be incorporated into a machine’s design or retrofitted on site with simple installation and easy-to-fit replacement parts available from stock.

Take a look

Why PU Conveyor Belt Cleaners & Scrapers?

- Monoblade Primary PU Cleaners

- Modular Primary PU Cleaners Interchangeable blades

- Secondary Tungsten Cleaner

- Reversible Secondary Tungsten Cleaner

- Long Service Life

Heavy duty blade designed to keep a cleaning edge as it wears

Basic Information

| Monoblade | Wall thickness – 5mm Outside diameter – 60.3mm Inside diameter – 50.3m |

| Modular | Wall thickness – 5mm Outside diameter – 48.3mm Inside diameter – 38.3mm |

| Secondary Tungsten Cleaner | German made tungsten carbide blade tips set at a non-aggressive 70 degree angle, mounted on rubber cushions. |

Want more information on our products?

Get In TouchResources

Learn more about PU Conveyor Belt Cleaners & Scrapers and how they cut carryback, reduce downtime, and keep your belts running at peak efficiency.