ZIP CLIP® FAQs

Explore some of our customers frequently asked questions & discover why ZIP CLIP® is now operating on more than 3500 mobile material processing machines around the world!

How long does ZIP CLIP® take to fit?

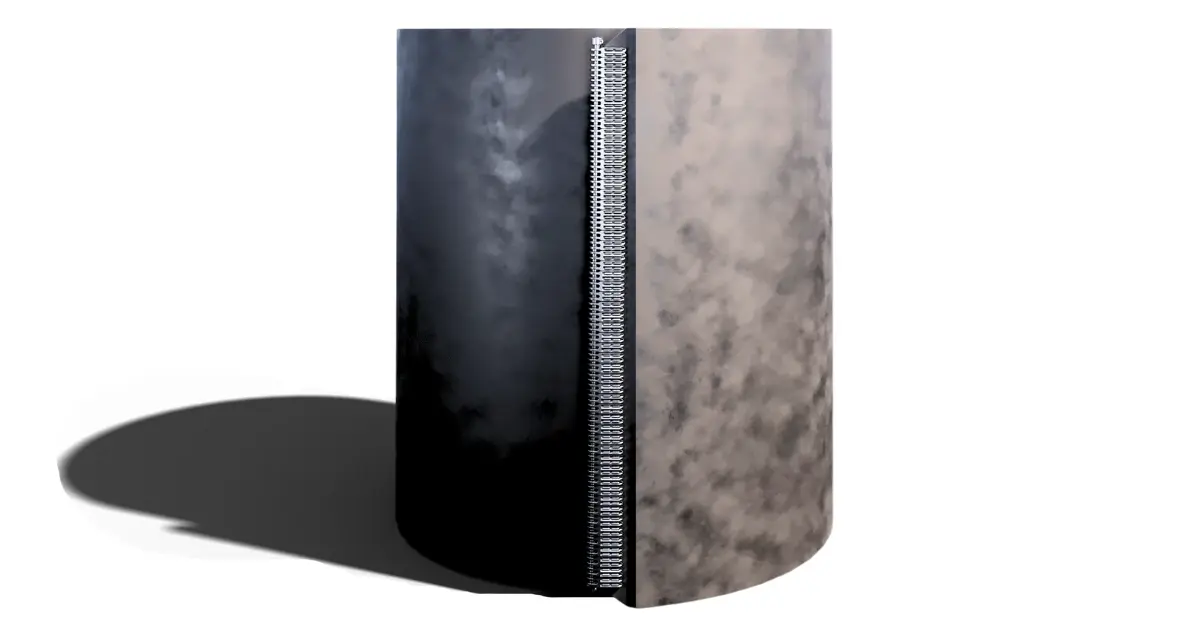

ZIP CLIP® Replacement Conveyor belts are supplied ready-to-fit. Supplied to the correct endless length and with the joint already prepared and clips pneumatically fitted to the conveyor belt in our factory, ZIP CLIP® can be installed and ready to run in just one hour. This is what makes ZIP CLIP® the World’s Fastest Replacement Conveyor Belt.

ZIP CLIP® Replacement Conveyor Belts can be fitted without any special training and is supplied with easy-to-follow fitting instructions.

How much money can I really save with ZIP CLIP®?

Having a ZIP CLIP® belt in stock can drastically reduce your downtime costs. Supplied ready-to-fit. ZIP CLIP® mechanically fastened conveyor belts can be installed and ready to run in just one hour without the need to wait for a vulcanizing team.

For example, in the event of a conveyor breakdown, one of our customers operating a limestone quarry could wait up to two days on a vulcanizing team, losing up to 16 hours of production at a cost of $2000 per hour. That’s $32,000 of lost revenue potential. With ZIP CLIP® ,the customer’s conveyor is back up and running within two hours – saving over $28,000.

But ZIP CLIP® is not just for mobile. Easier and safer to fit compared to vulcanized endless belts, many customers within industries such as static recycling plants are switching to ZIP CLIP® as they save money not just on a vulcanizing team and lost productivity but also on expensive lifting equipment required to carry out a vulcanized joint at height.

How long does a ZIP CLIP® belt last compared to its alternatives?

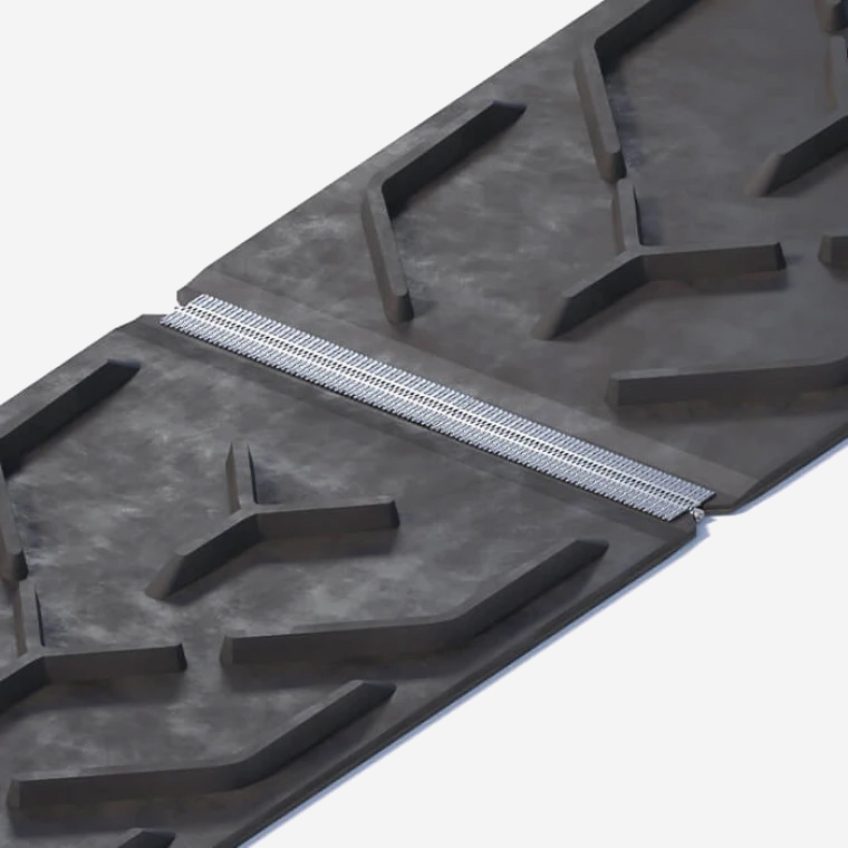

Mechanical fasteners fitted in the field can be tricky to install and often offer only a short-term solution. Problems with joint straightness and inconsistent pressure can result in the clips coming away from the belt over time and ultimately to joint failure.

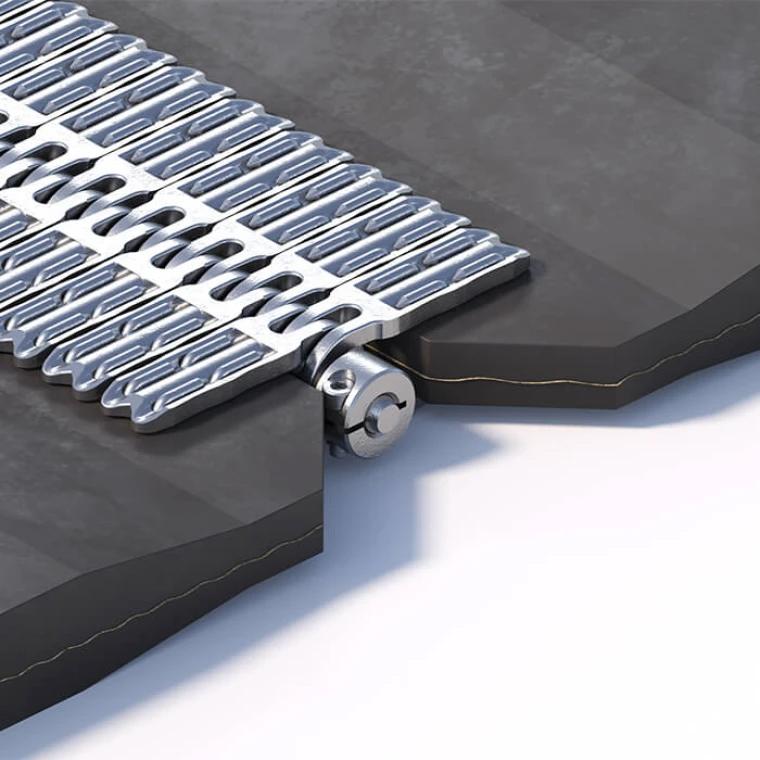

In contrast, ZIP CLIP® stainless steel staples are pneumatically inserted into the belt under factory conditions. This process ensures consistent tension across the joint and superior joint strength and wear life. Our testing shows that a ZIP CLIP® joint has the same or greater tensile strength than the belt itself.

What’s the wear life of a ZIP CLIP® compared to a vulcanized joint?

Rigorous testing demonstrates that ZIP CLIP® mechanically-fastened joint exhibits comparable tensile strength to hot vulcanized joints. With durable, German-engineered steel fasteners and an armored connecting pin, ZIP CLIP® designed to withstand the toughest conveying applications.

Many customers choose ZIP CLIP® as a permanent solution due to its ease of installation. Unlike on-site vulcanizing, which is expensive and time-consuming, ZIP CLIP® comes with all the necessary tools and instructions for quick installation.

Within an hour, you can be up and running, confident that your “replacement belt” can become a long-term fixture.

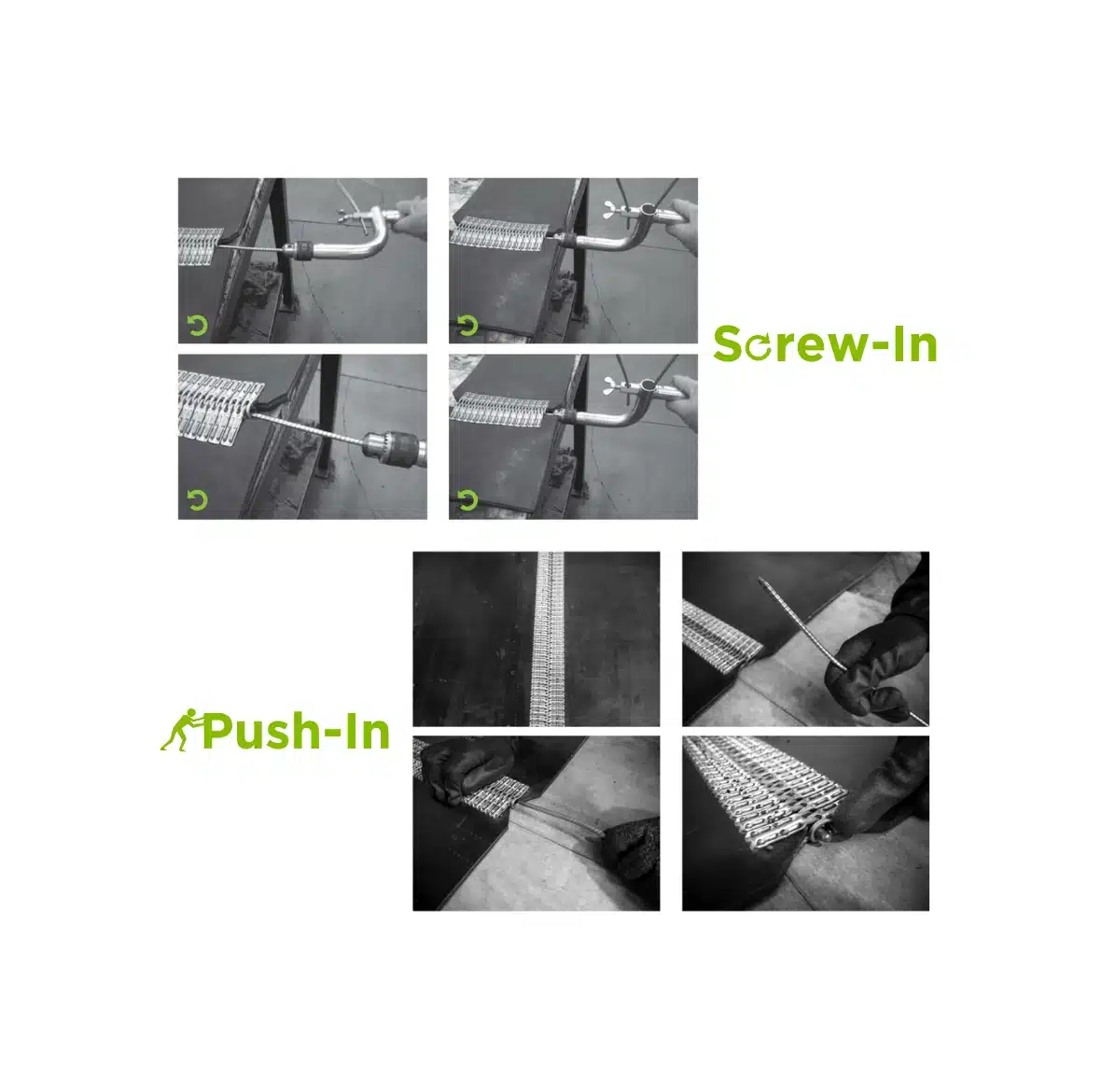

Screw-In or Push-In ZIP Belts – What's the Difference?

ZIP CLIP® replacement conveyor belts are fastened with an armored connecting pin, which is inserted into the clips, joining the two ends of the conveyor belt to make it endless. There are two types available—Screw-In and Push-In. The most common is Push-In, which, as the name suggests, is pushed or pulled through the clips to fasten the belt. Once inserted, two retaining collars are fixed to each end of the pin with an Allan key. This extra safety measure ensures the pin will not migrate while the conveyor is moving.

With the screw-in option, the pin has a thread and is secured in place with the pin insertion tool provided. Screw-In ZIP CLIP® belts are often recommended for use in fine material applications as the splice is sealed with Polyurethane—minimizing the sifting of fines.

How long does it take to get a ZIP CLIP® replacement conveyor belt?

We offer short lead times and a wide range of stock materials across all three of our global production centers.

If you need your ZIP CLIP® belt in a hurry, we offer same-day dispatch and expedited shipping options on request. We recommend keeping a ZIP CLIP® replacement belt in stock next to your most critical conveyor.

ZIP CLIP® Specifications

At Smiley Monroe, we stock a wide range of EP multi-ply belt specifications, including TOUGHFLEX® and FABRIC BREAKER belts designed for a wide range of conveying applications.

Customers across crushing, screening, recycling, and road construction are successfully running ZIP CLIP® belts.

ZIP CLIP® is also suitable to use with conveying applications with overband magnets.

How is ZIP CLIP® installed?

If you do experience a breakdown, ZIP CLIP® can be installed without specialist training in just one hour. Fitting instructions are supplied with every belt.

Check out this installation video, which demonstrates how easy fitting a ZIP CLIP® replacement belt is.

ZIP CLIP® Compatibility

Because ZIP CLIP® staples are recessed into the top cover of the conveyor belt in our factory, ZIP CLIP® is compatible with many common conveyor components such as PU belt cleaners.

ZIP CLIP® mechanically-fastened conveyor belts are also suitable for use with overband magnets.