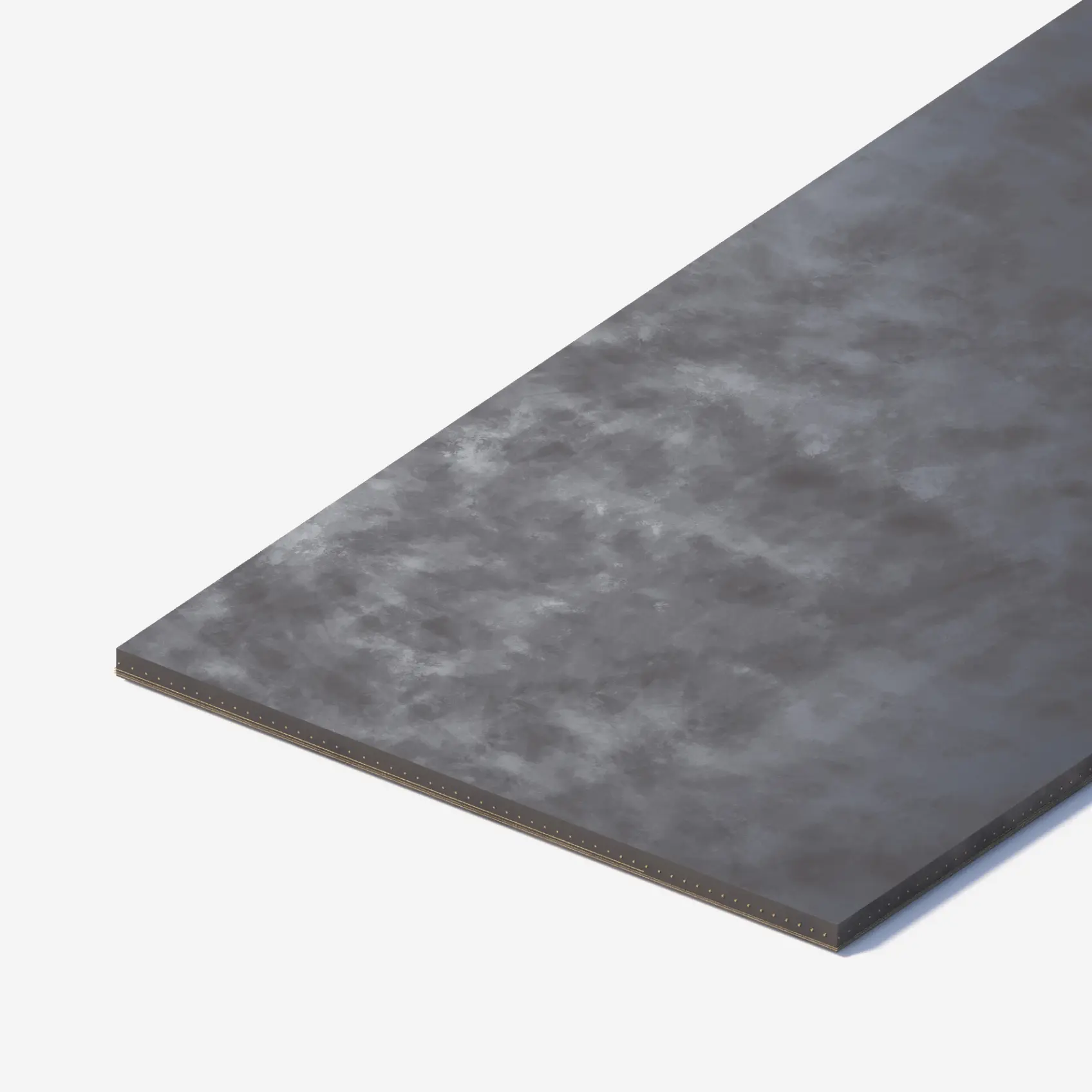

Ripstop belts

Rebar just met its match.

Designed for the harshest conveying applications.

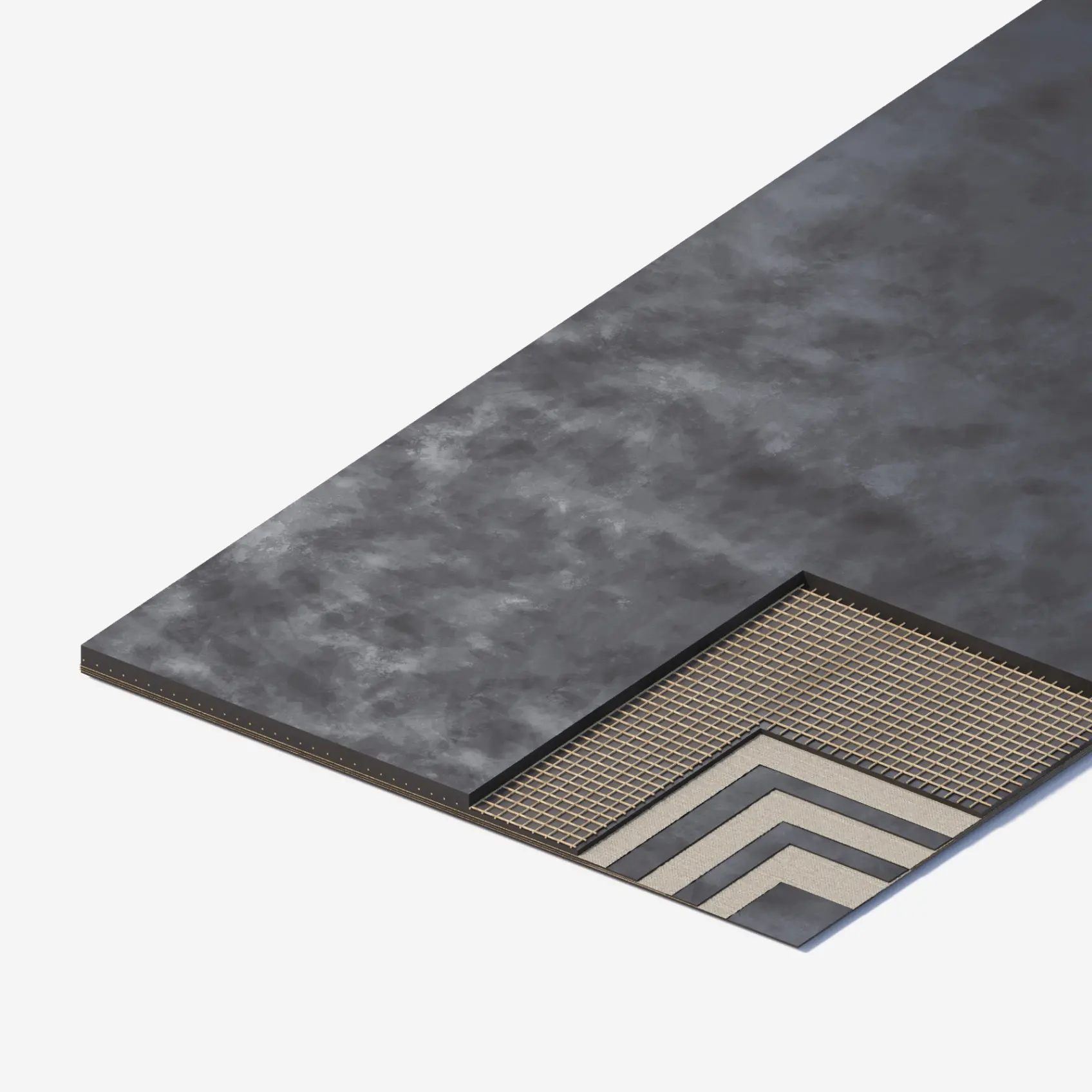

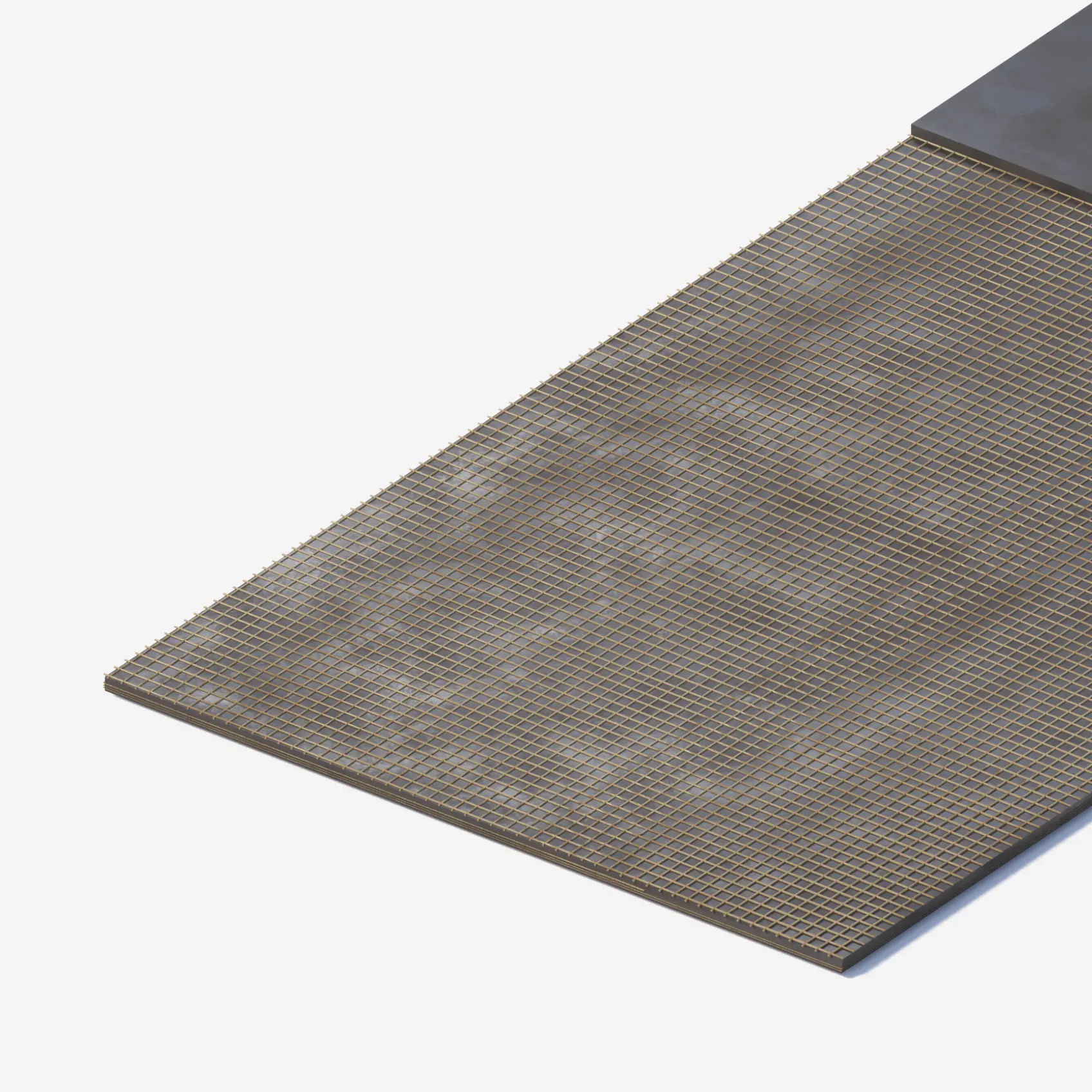

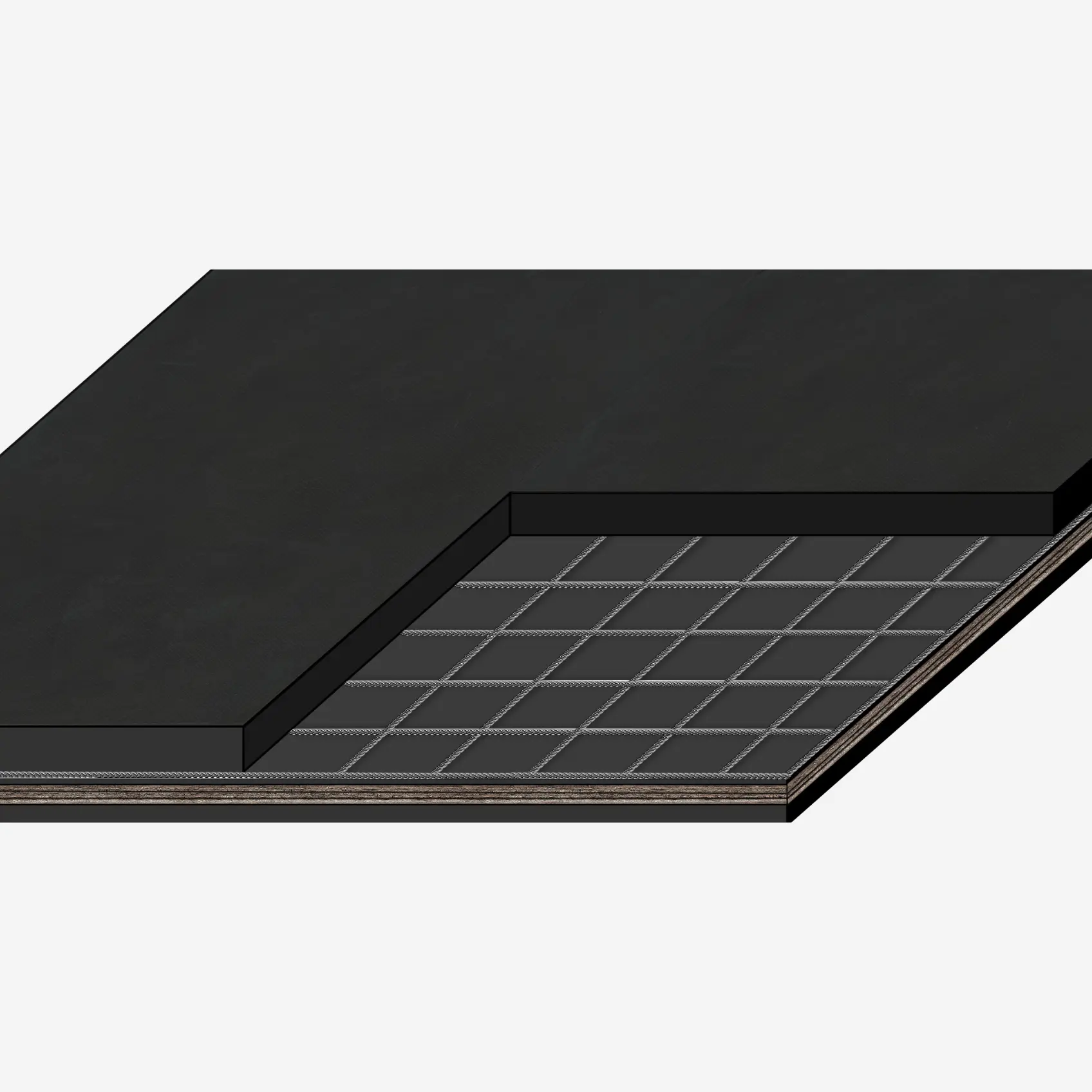

Constructed with synthetic fabric plies and an additional reinforced steel wire mesh for excellent rip and puncture resistance, Ripstop conveyor belts are ideal for handling the harshest construction and demolition materials for example where rebar is present.

Take a look

Why ripstop belts?

- Ideal for Construction and Demolition (C&D) waste materials e.g. rebar and concrete

- DIN 22102, IS0 9001, OHSAS 18001

- Warranty 12 months

Want more information on our products?

Get In TouchSPECIFICATIONS

| TensileStrength (N/mm2) | Ply | Top/Bottom covers (mm) | Stock Widths (mm) |

|---|---|---|---|

| EP400 | 3 + 1 | 4 + 2 | 800 |

| Ep500 | 3 + 1 | 8 + 2 | 800, 900, 1000, 1200 |

| Ep430 | 4 + 1 | 6 + 2 | 1400 |

Conveyor Belt Selection Chart

| ToughFlex® | Ripstop | Fabric Breaker | |

|---|---|---|---|

| Wear Resistance | Excellent | Good | Good |

| Impact Resistance | Excellent | Good | Good |

| Rip Resistance | Excellent | Excellent | Good |

| Puncture Resistance | Excellent | Good | Good |

| Cut Resistance | Excellent | Good | Good |

| Small pulley diameters | Excellent | Good | Good |

| Troughability | Excellent | Good | Good |

Resources

Learn more about Ripstop Belts and how they stand up to rebar, rubble, and the toughest C&D materials without missing a beat.