Zip Clip® Belts

The world’s fastest replacement conveyor belt.

Zip Clip® Belts

The world’s fastest replacement conveyor belt.

MEET US AT

Find us at Booth C32562

Don’t just clip It, ZIP CLIP® It.

ZIP CLIP® Is a ready-to-fit replacement belt from the Giants of Belting. Focused on maximizing machine uptime and reducing expensive vulcanizing bills, Smiley Monroe designed ZIP CLIP®—a mechanically fastened replacement belt that’s just as good as the original endless belt.

Supplied ready-to-fit, ZIP CLIP can be safely self-installed in under one hour with no specialist training. Once tensioned, it can be run Immediately. No vulcanizing, no waiting, no DIY fasteners. Instead, a replacement belt that’s as simple as changing a tire on your car.

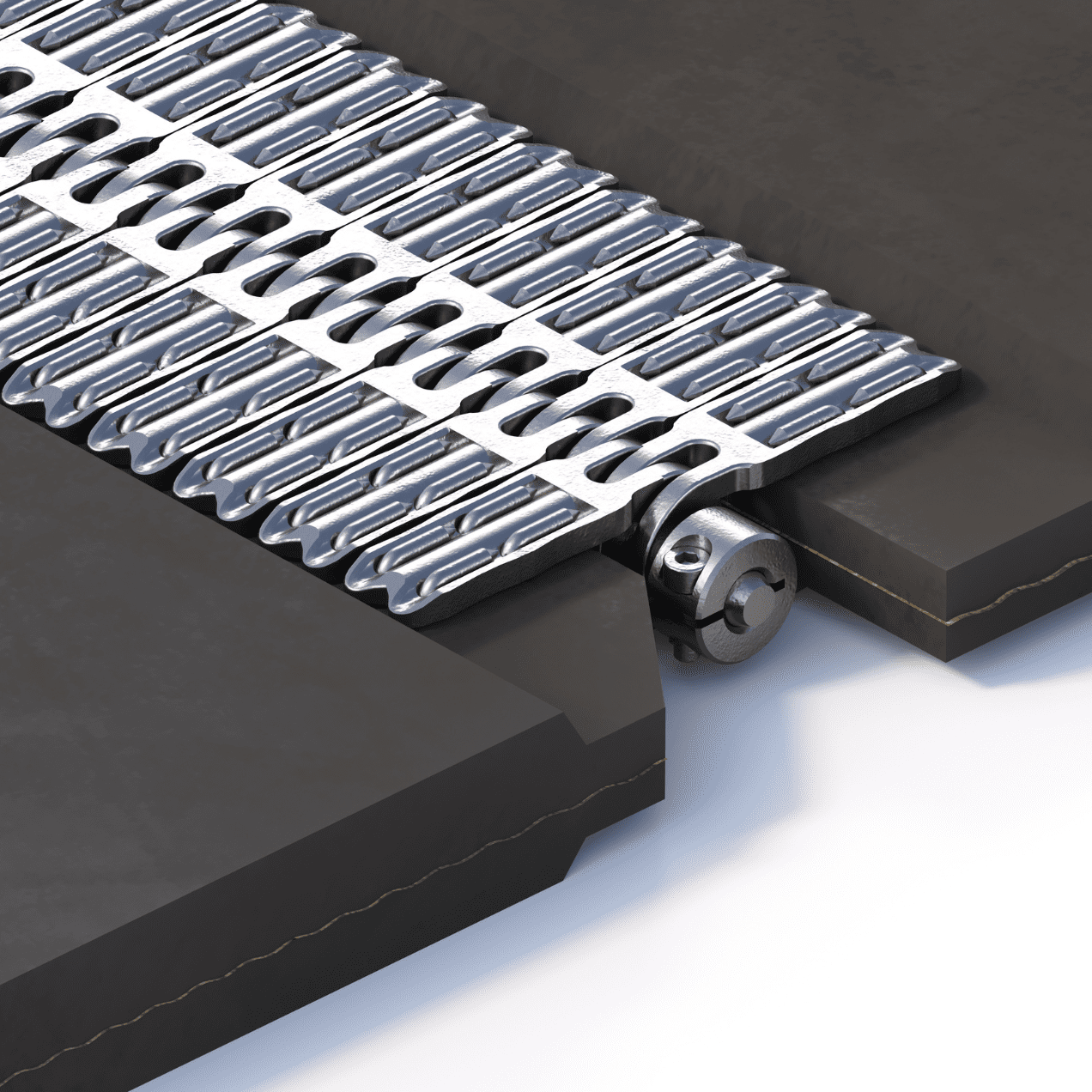

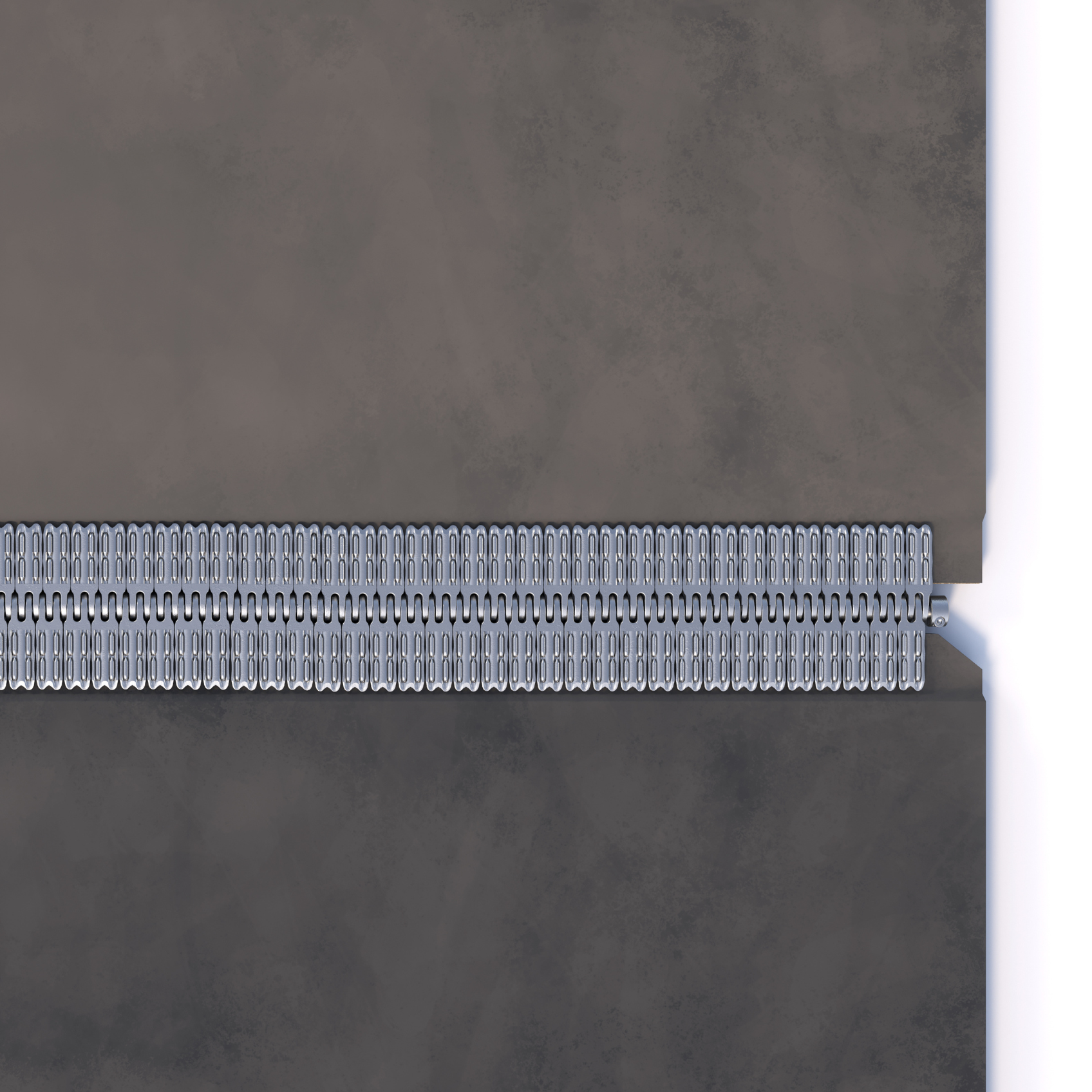

Safer, cheaper, and faster than vulcanizing on-site, ZIP CLIP’s mechanical joint can be fitted under any environmental conditions. Unlike traditional DIY fastener options, ZIP CLIP’s factory-prepared joint has even tension across the belt, reducing the risk of the belt tearing, and is proven to have the same or greater tensile strength than the belt itself.

Rather than being a temporary replacement, ZIP CLIP belts can be fitted and run for the long term, with many choosing the ZIP CLIP system as their primary conveyor belt option.

ZIP CLIP belts are being used across a range of industries, from static recycling plants to mobile crushing and screening applications.

ZIP CLIP® belts are being used across a range of industries, from static recycling plants to mobile crushing and screening applications.

Take a look

ZIP CLIP® Benefits

- Factory-prepared splice for superior strength

- PU Belt Cleaner friendly thanks to a recessed splice

- Suitable for use with over-band magnets

- Ideal for smaller tail pulleys

- Screw-in splice option to prevent sifting fines

- Wear, corrosion, and rust-resistant clips

- No specialist tools or training required

Applications

Industries worldwide use ZIP CLIP® replacement conveyor belts—from recycling plants to quarrying, road construction, and environmental applications.

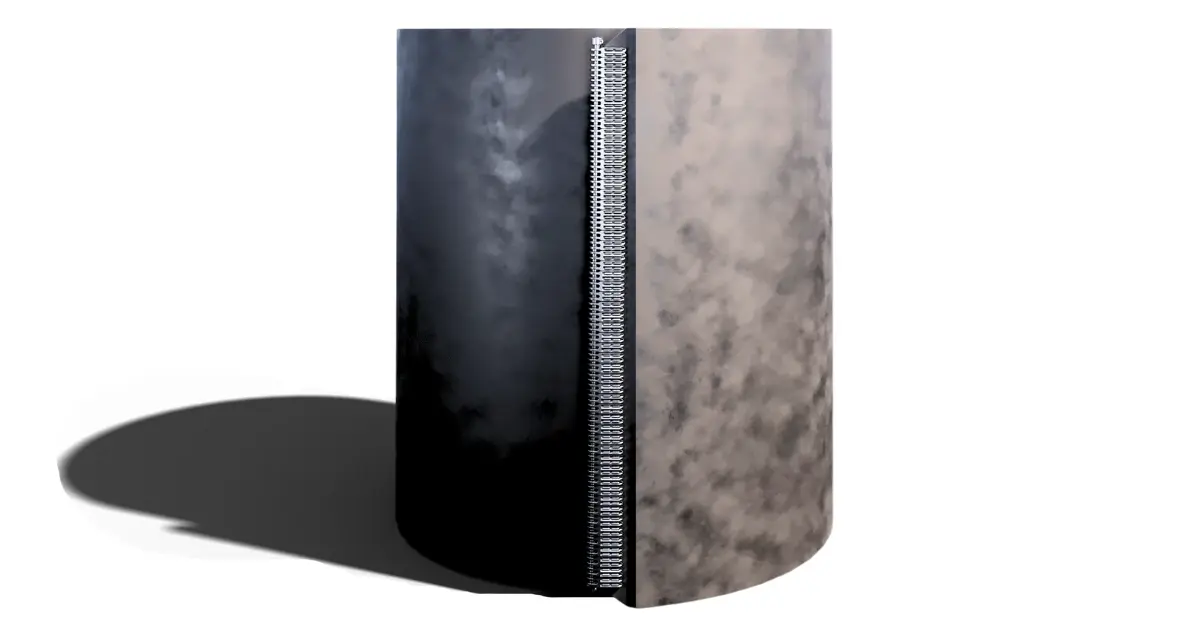

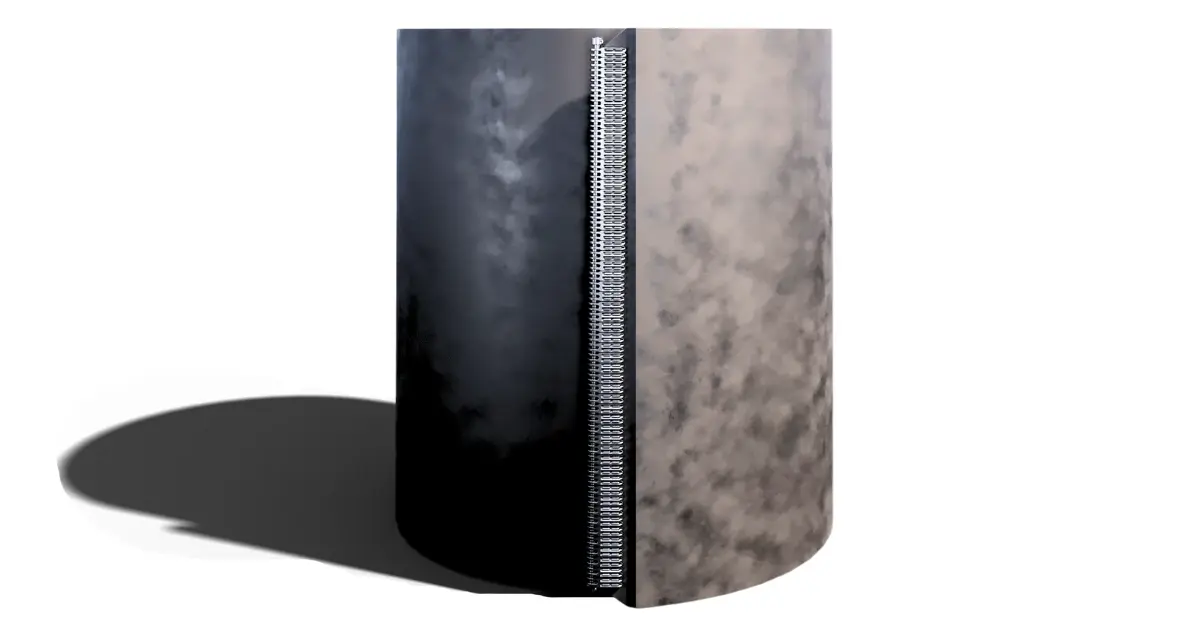

ZIP CLIP® replacement conveyor belts are fully customizable. They are available in a wide range of flat, chevron, and cleated base belt options and specifications—including special rubber covers with oil and heat resistance.

The range varies from EP Multi-ply belts for transporting screened sand and aggregates to Fabric Breaker and Ripstop. ZIP CLIP® is also available in our EPP ToughFlex® range belt built for the harshest conveying applications.

Applications

Industries worldwide use ZIP CLIP® replacement conveyor belts—from recycling plants to quarrying, road construction, and environmental applications.

ZIP CLIP® replacement conveyor belts are fully customizable. They are available in a wide range of flat, chevron, and cleated base belt options and specifications—including special rubber covers with oil and heat resistance.

The range varies from EP Multi-ply belts for transporting screened sand and aggregates to Fabric Breaker and Ripstop. ZIP CLIP® is also available in our EPP ToughFlex® range belt built for the harshest conveying applications.

How much could you save with ZIP CLIP®?

Conveyor downtime is costly, not only in terms of lost revenue but also in expensive vulcanizing and maintenance bills. By stocking a ZIP CLIP® replacement conveyor belt, you could be back up and running within one hour—without the need to wait on vulcanizing teams. Installation is safe and speedy, making it no surprise that many of our customers choose to run ZIP CLIP® on their most critical conveyors.

What problems do zip clip® replacement conveyor belts solve?

We designed ZIP CLIP® Replacement Conveyor Belts for quick and easy installation, reducing planned and unplanned downtime. Installation can be completed in under an hour, with no need for vulcanising or specialist tools—perfect for quickly getting your operation back online.

Other products to reduce downtimeZIP CLIP® Replacement Conveyor Belts offer safe and speedy installation from the ground. You can fit ZIP CLIP® from the ground without scissor lifts—even in tight spaces or on elevated conveyors like those in recycling plants. For mobile plants, where the conveyor cassette usually has to be removed for vulcanizing, ZIP CLIP® lets you fit the belt with the conveyor intact—saving time and improving site safety.

ZIP CLIP® is a fast-fit solution for on-site teams. It enables maintenance crews to carry out replacements with minimal equipment and no external contractors—ideal for remote locations and urgent repairs.

By extending the lifespan of your conveyor system and reducing the need for frequent belt replacements or equipment downtime, ZIP CLIP® also supports your sustainability targets—helping to cut waste, lower emissions, and reduce energy consumption.

Find your nearest dealer

2-10 Bridge St, Belfast, BT1 1LU

Northern Ireland, UK

2-10 Bridge St, Belfast, BT1 1LU

Northern Ireland, UK

Want more information on our products?

Get In TouchResources

Learn more about ZIP CLIP® and how it can save your business thousands in lost time and productivity.